Unlocking the Potential of Industrial Blades for Sale

Industrial blades are a quintessential element in various manufacturing and industrial processes. They are engineered to provide precision, durability, and efficiency, making them an essential tool for professionals in numerous sectors. In this comprehensive guide, we delve into the essentials of industrial blades, their applications, and why choosing the right blade can significantly enhance your operational effectiveness.

Understanding Industrial Blades

At their core, industrial blades are cutting tools used in numerous applications. These blades come in various shapes, sizes, and materials, each tailored to specific tasks. The right choice of blade can make a striking difference in terms of performance, longevity, and cost-effectiveness.

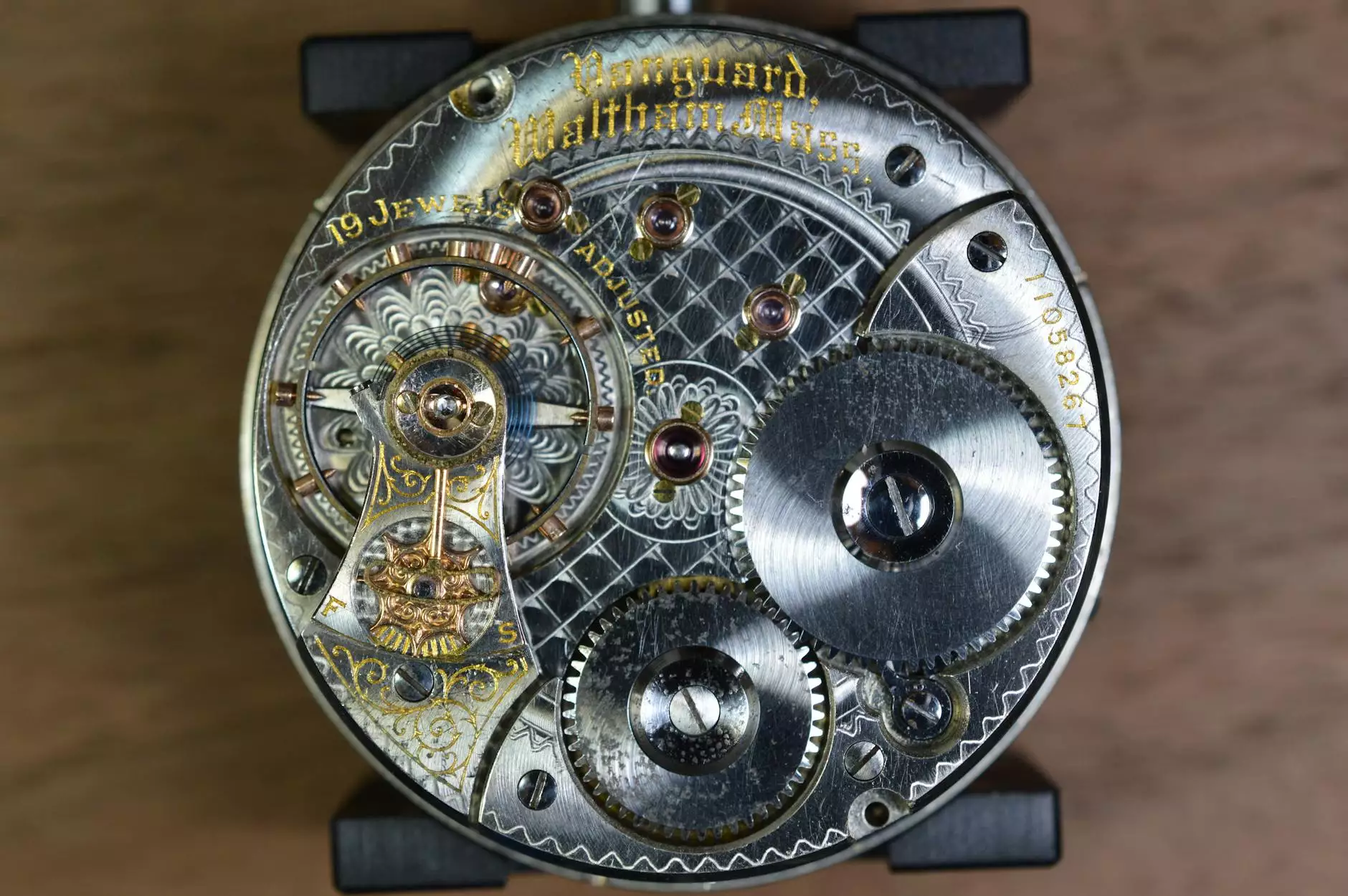

The Anatomy of Industrial Blades

- Material: Common materials include high-speed steel (HSS), carbide, and stainless steel, each offering unique benefits like hardness, wear resistance, and corrosion resistance.

- Blade Type: Different tasks require different blade types—band saw blades, circular blades, and knife blades are among the most popular.

- Size and Thickness: The dimensions of blades are crucial; a proper fit allows for smoother cuts and reduced wear on equipment.

Why Quality Matters

Choosing high-quality industrial blades for sale directly impacts productivity. Low-quality blades can lead to frequent breakdowns, resulting in downtime and increased costs.

Applications of Industrial Blades

Industrial blades are utilized across a multitude of sectors. Understanding the specific applications can help businesses select the most appropriate blades for their needs.

1. Food Processing Industry

In food processing, blades are crucial for slicing, dicing, and packaging. High-quality, stainless steel blades ensure hygiene while maintaining sharpness for clean cuts.

2. Woodworking

Woodworking requires precision cutting tools like band saws and circular saw blades. Choosing the right blades for cutting different types of wood ensures clean cuts and reduces material waste.

3. Metal Fabrication

In metal fabrication, blades such as hacksaw blades and mechanized blades are essential for cutting and shaping metal. The hardness and durability of the blades determine the efficiency of the process.

4. Textile Manufacturing

The textile industry employs industrial blades for cutting fabrics with precision. Blades designed for textiles are crafted to handle various fabric types without fraying the edges.

Benefits of Industrial Blades

Understanding the benefits of using industrial blades for sale can guide your purchasing decision. Here are some compelling advantages:

- Increased Efficiency: Quality blades cut faster and smoother, leading to improved productivity.

- Cost-Effectiveness: Investing in high-quality blades reduces the frequency of replacements and repairs, ultimately saving money in the long run.

- Precision Cutting: Well-designed blades provide clean cuts, which is crucial for industries where accuracy is paramount.

- Safety: Quality blades are less likely to break or cause accidents, enhancing workplace safety.

Knife Sharpening: Keeping Your Blades in Top Shape

Even the best industrial blades require maintenance to perform optimally. Knife sharpening is an essential service that can significantly extend the life of your blades.

Why Knife Sharpening Matters

Knife sharpening restores the edge of your blades, ensuring they cut efficiently. Dull blades not only slow down production but can also lead to hazards in the workplace.

Professional Knife Sharpening Services at SZ Blade

At SZ Blade, we offer expert knife sharpening services to cater to various industrial blades. Our skilled professionals utilize advanced techniques and equipment to ensure your blades are sharpened to perfection.

Choosing the Right Industrial Blades for Your Business

Selecting the right industrial blades for sale involves several considerations:

- Application: Identify the specific cutting tasks you need the blades for.

- Material: Choose the appropriate material based on the material you’ll be cutting.

- Size: Ensure the blades fit your equipment correctly.

- Brand Reputation: Opt for reputable manufacturers known for quality and durability.

Conclusion: Invest in Quality for Long-Term Success

Investing in high-quality industrial blades for sale and proper knife sharpening services is crucial for businesses aiming for efficiency and effectiveness in their operations. At SZ Blade, we pride ourselves on providing not just the blades but the expertise necessary to keep your operations running smoothly.

With a diverse range of high-quality industrial blades available and professional knife sharpening services, we are committed to helping your business achieve its operational goals. Visit us today at SZ Blade to learn more about our offerings and how we can support your business needs.