Molding Precision: Elevating the Standards in Metal Fabrication

In the highly competitive landscape of business today, achieving a distinct edge is essential, especially within the domain of metal fabricators. One of the most critical components that sets successful businesses apart in this industry is "molding precision". This term encompasses not only the techniques and technologies employed but also the quality of the final products delivered to clients.

Understanding Molding Precision

"Molding precision" refers to the accuracy and consistency in the metal fabrication process, primarily achieved through advanced techniques and tools. In essence, it is the art and science of shaping materials to meet stringent specifications, thus ensuring that every component is made to the highest quality standards. Precision in molding is vital for a variety of reasons, including:

- Quality Control: Ensures that each product meets predefined specifications.

- Cost-Efficiency: Minimizes waste and reduces production costs.

- Brand Reputation: Enhances trust and reliability among clients.

- Timeliness: Improves production timelines through streamlined processes.

The Importance of Precision in Metal Fabrication

In the realm of metal fabrication, precision is not just a desirable trait; it is a necessity. Businesses that prioritize molding precision can expect to experience numerous advantages, including:

1. Enhanced Product Quality

When metal fabricators utilize precise molding techniques, they create products that not only meet but exceed customer expectations. High-quality products result from meticulous attention to detail and adherence to design specifications.

2. Increased Efficiency

Precision molding contributes to an overall increase in operational efficiency. By utilizing tools and machinery that allow for fine-tuned adjustments, fabricators can reduce the time spent on corrections and reworks.

3. Safety and Reliability

Components crafted with high precision significantly improve safety and reliability in their end applications. In industries such as aviation, automotive, and construction, where the margin for error is slim, precision can save lives and prevent costly failures.

How Molding Precision Transforms Metal Fabrication Processes

The transformation brought about by molding precision extends beyond quality enhancements—it's about redefining process capabilities. Here are some key aspects:

Advanced Technologies

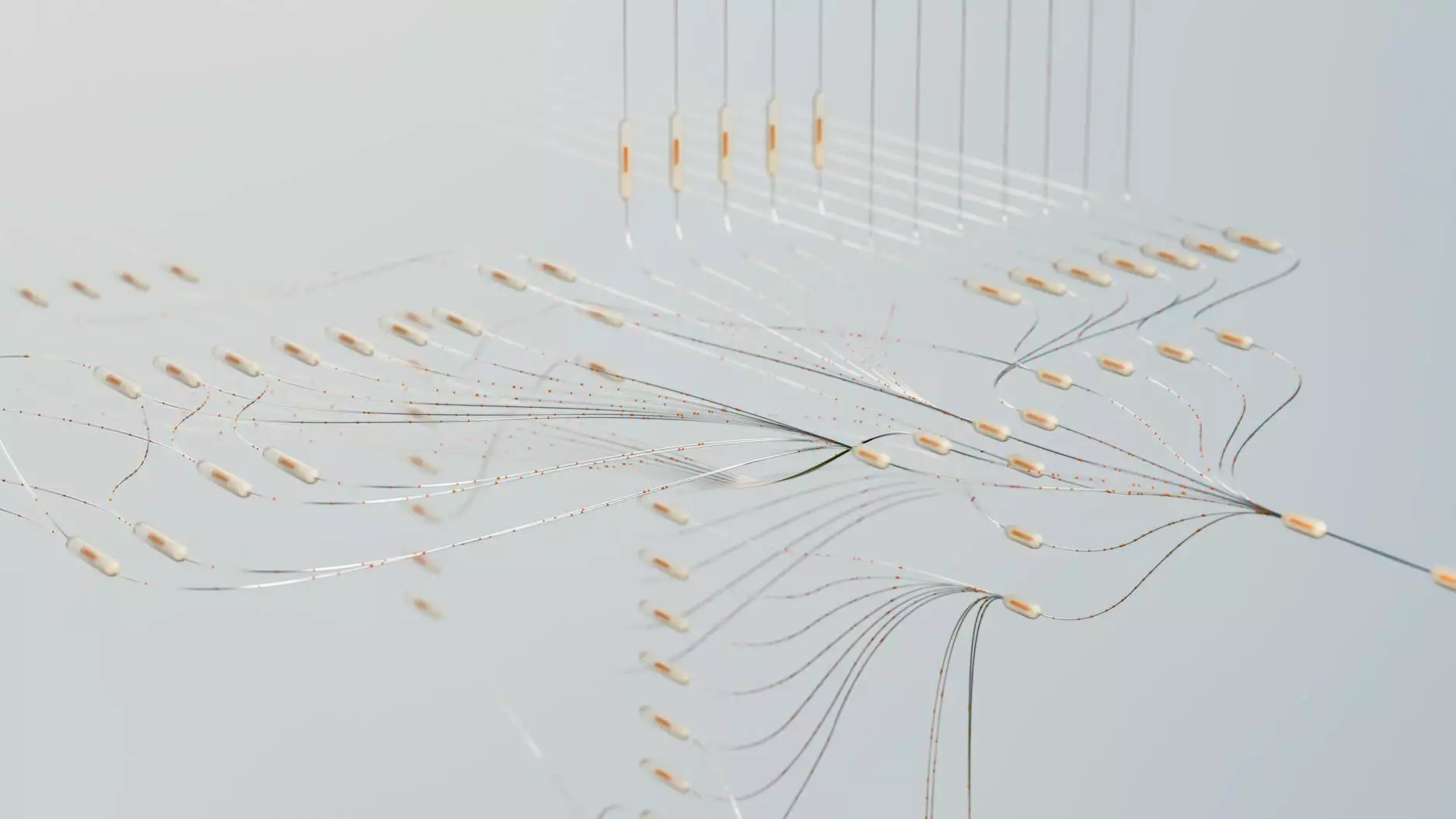

The introduction of advanced manufacturing technologies, such as 3D printing and computer numerical control (CNC) machining, has revolutionized the metal fabrication landscape. These technologies allow for:

- Complex Designs: Ability to create intricate geometries that were previously unachievable.

- Rapid Prototyping: Speedy testing of designs, allowing for quicker iteration and innovation.

- Automation: Reduced human error and enhanced production speed.

Skilled Workforce

While technology plays a vital role, the importance of a skilled workforce cannot be understated. Metal fabricators need technicians who are adept at operating precision machinery and who understand the nuances of molding processes. Continuous training and development are essential for maintaining high standards of precision.

Case Study: The Impact of Molding Precision at DeepMould.net

At DeepMould.net, the commitment to molding precision is exemplified through their meticulous processes. By integrating state-of-the-art equipment with a highly trained workforce, DeepMould has successfully transitioned to precision metal fabrication. Here’s how:

Innovative Process Implementation

DeepMould.net’s adoption of cutting-edge techniques such as CNC machining has allowed them to achieve greater consistency in their products. Every piece is crafted with exacting standards, which greatly enhances the overall quality of their offerings.

Customer-Centric Approach

DeepMould reinforces its business model based on customer satisfaction. The precision with which they mold metal ensures that their clients receive components that integrate seamlessly into their operations. Positive customer feedback has propelled the reputation of the company to new heights.

Future Trends in Molding Precision

The field of metal fabrication is continually evolving, and molding precision will adapt to meet future demands. Some emerging trends to watch for include:

1. Sustainable Practices

With an increasing emphasis on sustainability, businesses will need to adopt precision practices that minimize waste and optimize resource usage. This shift not only benefits the environment but also reduces operational costs.

2. Smart Manufacturing

The rise of the Internet of Things (IoT) and smart technologies has the potential to revolutionize molding precision by enabling real-time monitoring and adjustments, thus enhancing quality and reducing downtime.

3. Customization and Personalization

As demand for personalized products rises, molding precision will facilitate the creation of custom solutions tailored to specific customer needs. This ability to innovate and adapt quickly is crucial for maintaining competitiveness in the market.

Conclusion: The Path Forward in Molding Precision

In conclusion, the concept of molding precision is foundational to the success of any business within the metal fabrication industry. By focusing on quality, efficiency, and advanced technologies, companies like DeepMould.net are leading the way toward a more productive and profitable future.

Investing in precision molding techniques not only enhances product quality but also builds a robust reputation that attracts and retains clients. As the industry moves forward, embracing innovation and skilled craftsmanship will be crucial strategies for achieving lasting success. By prioritizing molding precision, businesses can ensure they remain at the forefront of the metal fabrication sector, delivering exceptional results and unparalleled value.